PGI’s Quality Management System is certified to the strict AS9100

standards but flexible enough to comply to most any quality

standards required by the customer. PGI’s standards are regularly

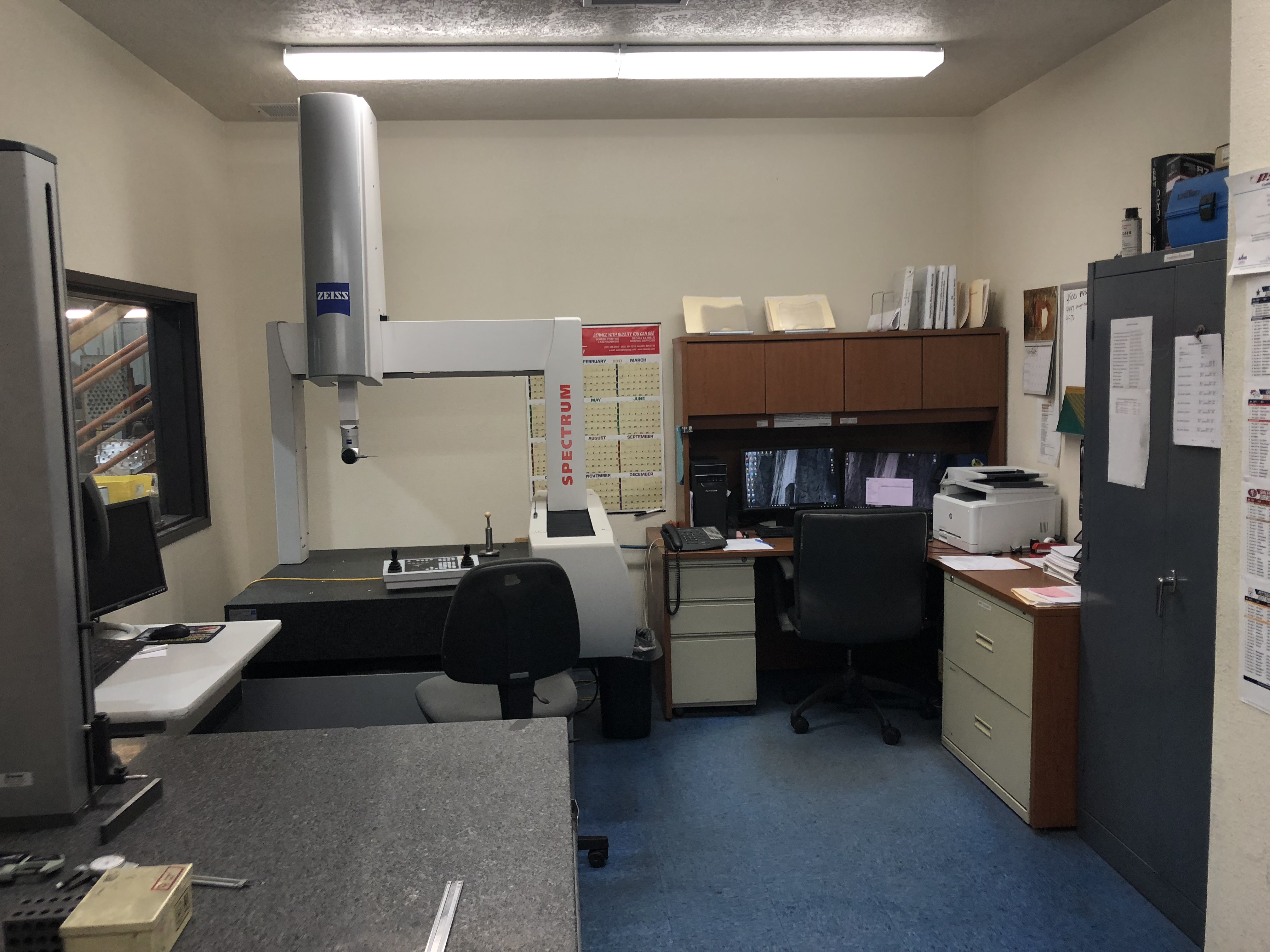

calibrated by NIST Standards. PGI also has a temperature

controlled inspection room to control close tolerances for materials

that are sensitive to Coefficient of Expansion . The Zeiss Contura is a 5 axis programmable Coordinate Measuring Machine which

is capable of checking parts to the .0001 as well serving as a great

tool for reverse engineering.

Certifications: AS9100 2022

Directorate of Defense Trade Controls

PGI has internal controls built in it’s quality system to efficiently comply to ITAR regulations

Supplier Purchase Order Terms and Conditions:

By accepting our purchase order, it is understood that your organization agrees to meet the following AS9100 requirements: 1. PGI reserves the right of final approval of product, procedures, processes, and equipment. 2. Suppliers initially approved for use via Certification (ISO, AS9100, ISO 17025, AS9120, etc.) must notify our organization of any changes to that certification. 3. The Supplier shall maintain on file and make available to (upon request) PGI, its customers, and/or regulatory authority, all quality data/records such as certificates of material and/or processes, acceptance test reports, inspection records, control plans and other applicable quality control data for a minimum of 15 years from completion of purchase order that directly affects the quality of parts/services ordered by PGI unless otherwise noted on the PO. 4. To ensure product identification and traceability, PGI requires material certificates, certificates of conformity, and/or supporting documentation from its suppliers as is appropriate. These requirements will be specified on the purchase order. 5. PGI’s external providers are to apply the appropriate controls to their direct and sub-tier external providers to ensure that product requirements are met. The appropriate controls may include customer/regulatory/AS9100 specific requirements and will be indicated on PGI purchase order 6. PGI may require a Corrective Action Report from its suppliers when nonconforming material/product/service is discovered. Specific actions may be implemented where timely and/or effective corrective actions to a supplier issue are not achieved. Delivery, quality i.e. non-conformances or any other actions detrimental to the integrity of PGI’s QMS or its customers are measured to the necessary quality metrics to maintain the best possible product. PGI expects 100% on time delivery. An on-time delivery of 85% or less and/or non-conformances of more than two per year, PGI may issue a corrective action. PGI expects 100% product quality. A supplier with a quality rating of 90% or less, PGI may issue a corrective action. PGI conducts supplier evaluations every six months. If a supplier is identified with a 85% or less rating, supplier may be notified and will have one month to correct the issue before a corrective action may be issued. Supplier’s annual on time delivery and non-conformance record is available upon request. If the delivery cannot be met, PGI must be notified in advance. These actions may include, but are not limited to, removal of the supplier from the approved supplier list. 7. Notify PGI of nonconforming product immediately upon discovery, including any latent defects in products already delivered to PGI. 8. Obtain PGI approval for nonconforming product disposition. All parts that are dispositioned as nonconforming must be identified with a discrepant part tag or other means of identification. 9. PGI, its customers, and/or any regulatory authority, shall have the right of access to the supplier’s facility and all applicable records for parts/services purchased by PGI. 10. The Supplier shall provide packaging in accordance with the best commercial packing methods to protect the product from damage, and for safety in handling during the shipping process or, per specific instructions as noted on our PO. 11. All provisions of these Terms and Conditions have been established to ensure success for PGI and its supply partners. 12. The Seller shall not furnish suspect counterfeit or counterfeit goods, materials to the Buyer under this Contract. All material delivered under this Contract shall be authentic and traceable to the original manufacturer. The Seller shall provide authenticity and traceability records to the Buyer upon request. The Seller shall immediately notify the Buyer if the Seller cannot provide goods, materials traceable to the original manufacturer. Upon receipt of such notification, the Buyer reserves the right to terminate this Contract at no cost to the Buyer or require specific material validation test and inspection protocol requirements to the Seller. 13. If suspect counterfeit or counterfeit goods, materials are furnished under this Contract and are found in any of the goods, materials delivered hereunder, such items will be impounded by the Buyer. The Seller shall promptly replace such suspect/counterfeit goods, materials with goods, materials acceptable to the Buyer. The Seller shall be liable for all costs relating to the removal and replacement of said goods, material, including, without limitation, the Buyer’s external and internal costs of removing such suspect/counterfeit goods, materials, and of any testing or validation necessitated by the replacement of the Seller’s Goods after suspect/counterfeit goods, materials goods, materials have been exchanged. The Buyer’s remedies described herein shall not be limited by any other Clause agreed upon between the Buyer and the Seller in this Contract and are in addition to any remedies the Buyer may have at law, equity or otherwise under this Contract. At the Buyer’s request, the Seller shall return any removed suspect counterfeit or counterfeit goods, materials to the Buyer in order that the Buyer may turn such parts over to its customer for further investigation. 14. The Seller agrees to insert the substance of this Clause, including this sentence, in any lower tier subcontract. 15. The Supplier, including any officers, employees or subcontractors while engaged in work related to this subcontract shall comply with all applicable laws, regulations and the terms of the subcontract and conduct themselves with the highest degree of ethics, integrity and honesty and treat others with respect and dignity, and create an environment free from discrimination, harassment, threats, violence, bullying, intimidating conduct or other similar behavior. 2/17/22